Company Profile

Taizhou Jinhao Axle Co., Ltd. has been dedicated to the R&D and production of electric vehicle drive axles for over 10 years. Our products are applied for a wide range of vehicles, including passenger cars, logistics vehicles, golf carts, sightseeing vehicles, road sweepers, and forklifts. With our extensive industry experience and in-depth product knowledge, Jinhao has earned a reputation as a trusted supplier in the sector.

We are committed to producing high-performance drive axles, with 100% of our gears undergoing precision grinding. This ensures smoother transmission, significantly reduced noise, and enhanced durability, making our axles ideal for a wide range of demanding applications. Whether it's the high-frequency operation of urban logistics vehicles or the precise control required for golf carts, our products deliver reliable and outstanding performance.

We are committed to producing high-performance drive axles, with 100% of our gears undergoing precision grinding. This ensures smoother transmission, significantly reduced noise, and enhanced durability, making our axles ideal for a wide range of demanding applications. Whether it's the high-frequency operation of urban logistics vehicles or the precise control required for golf carts, our products deliver reliable and outstanding performance.

We are committed to producing high-performance drive axles, with 100% of our gears undergoing precision grinding. This ensures smoother transmission, significantly reduced noise, and enhanced durability, making our axles ideal for a wide range of demanding applications. Whether it's the high-frequency operation of urban logistics vehicles or the precise control required for golf carts, our products deliver reliable and outstanding performance.

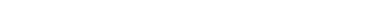

Production & Manufacturing

High Efficient Production Line

Our axle production line uses advanced automated equipment from raw material handling to final assembly. With precise CNC machining and 100% gear grinding, we ensure every axle meets high standards for smooth transmission, durability, and low noise. The line includes rigorous testing for load, endurance, and environmental conditions to guarantee quality performance.

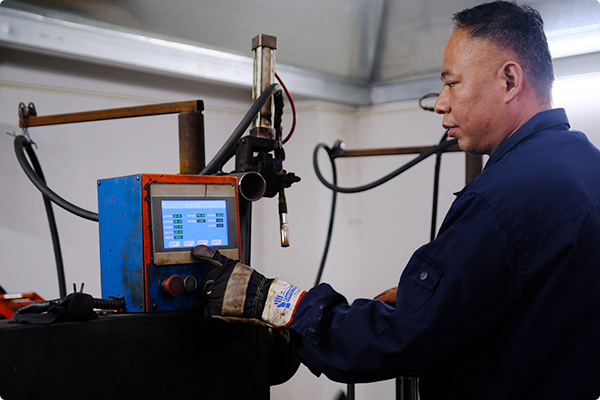

Precision Engineering & Rigorous Testing

Before delivery, each axle undergoes comprehensive inspections, including checks on transmission efficiency, noise levels, durability, and load capacity. Our testing replicates real-world conditions using 3D measurement tools to ensure every component meets precise standards, ensuring reliable performance for our customers.