Production &

Manufacturing

High Efficient Production Line

Our axle production line uses advanced automated equipment from raw material handling to final assembly. With precise CNC machining and 100% gear grinding, we ensure every axle meets high standards for smooth transmission, durability, and low noise. The line includes rigorous testing for load, endurance, and environmental conditions to guarantee quality performance.

Precision Engineering & Rigorous Testing

Before delivery, each axle undergoes comprehensive inspections, including checks on transmission efficiency, noise levels, durability, and load capacity. Our testing replicates real-world conditions using 3D measurement tools to ensure every component meets precise standards, ensuring reliable performance for our customers.

Efficient & Energy-Saving

Powerful Performance

High Load Capacity

Efficient & Energy-Saving

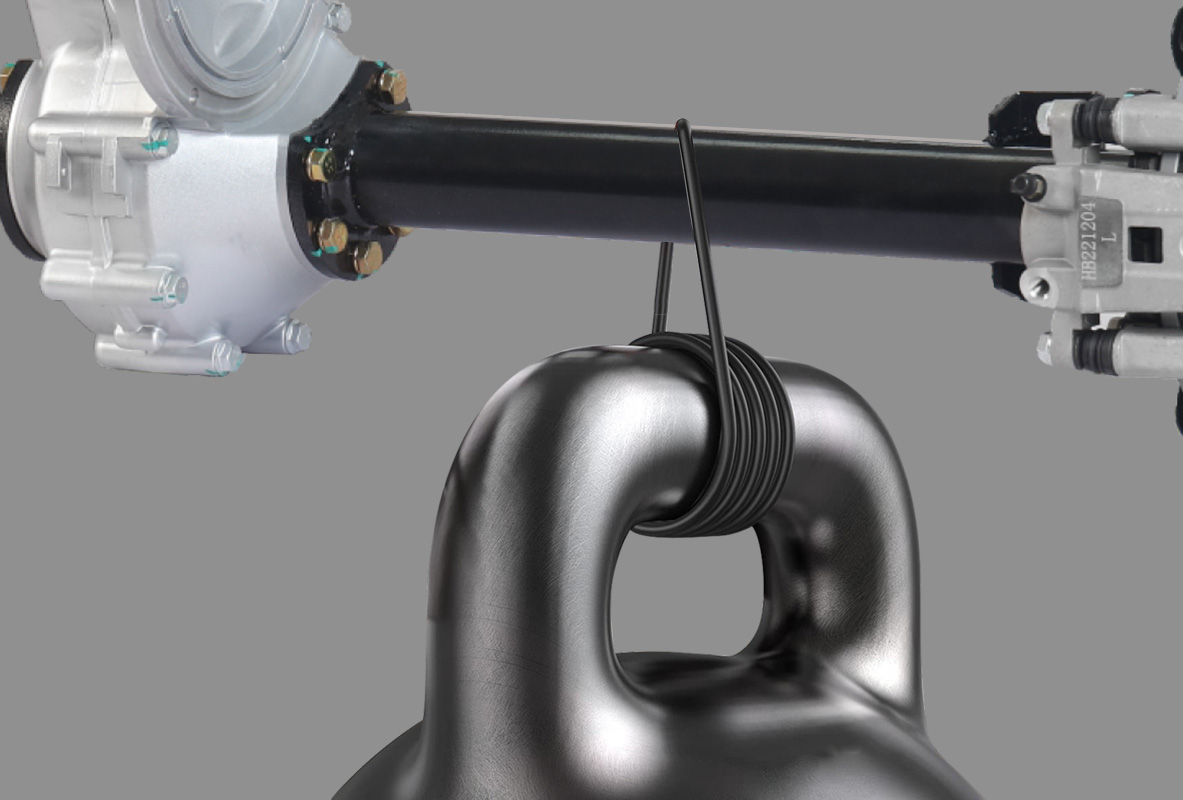

This rear axle features two half-bridges, allowing for precise differential motion. It not only supports the wheels but also ensures smooth and efficient power delivery to the rear wheels, enhancing vehicle performance.

Powerful Performance

Depending on the motor layout, it can feature centralized motors, wheel-side motors, or ISG motors, commonly found in hybrid vehicles, delivering robust power and efficiency.

High Load Capacity

Wheel-side motors feature electromechanical integrated drive systems, supporting four-wheel drive configurations with wheel hub motors for enhanced load capacity and performance.

NEWS & EVENT

Stay informed about the latest developments